Radio Clock Retrofit

It is important to note that this modification only works within the broadcasting range of the DCF77 long-wave time signal transmitter located in Frankfurt am Main in Germany. According to their website, effectively this is up to approximately 2,000 km but depending on atmospheric conditions, the signal may be picked up further away.

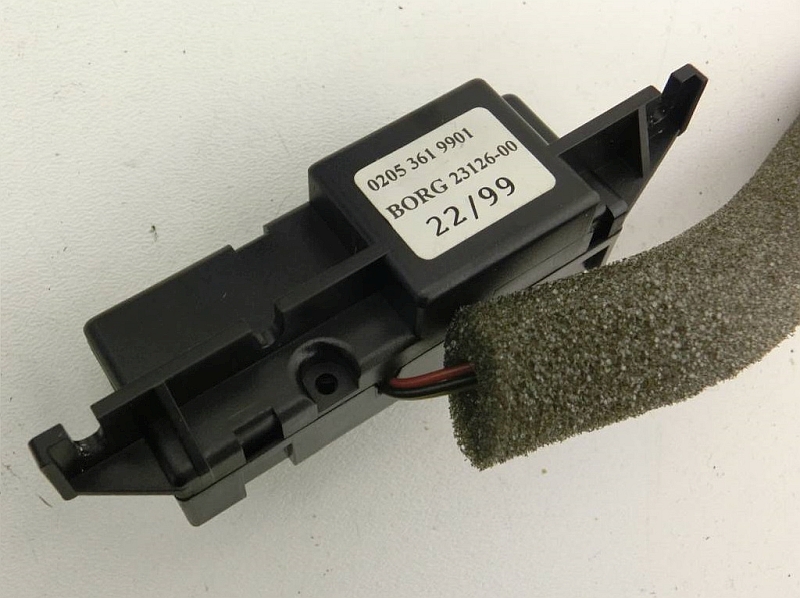

Please also note the important information under the "DCF77 Aerial" section below to obtain the correct version that has been tested and works with the circuitry detailed here.

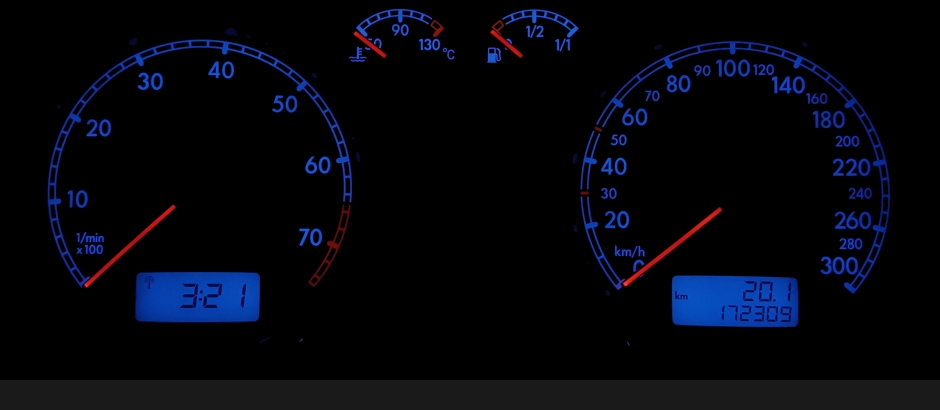

Some Sharan's and T5 Transporter's had the option of synchronising the clock display to this DCF77 time signal. This keeps the clock display within 3 milliseconds of the correct atomic time. This is a fairly common option on Audi's and it is also possible to retrofit to VW instrument clusters as detailed below.

Before you go to all the trouble of installing the components make sure you actually have the "radio tower" icon in the top left hand corner of the LCD clock display. You can see it if you shine a torch onto the display and it will also actually light up if you perform an Output Test of the instrument cluster with VCDS.

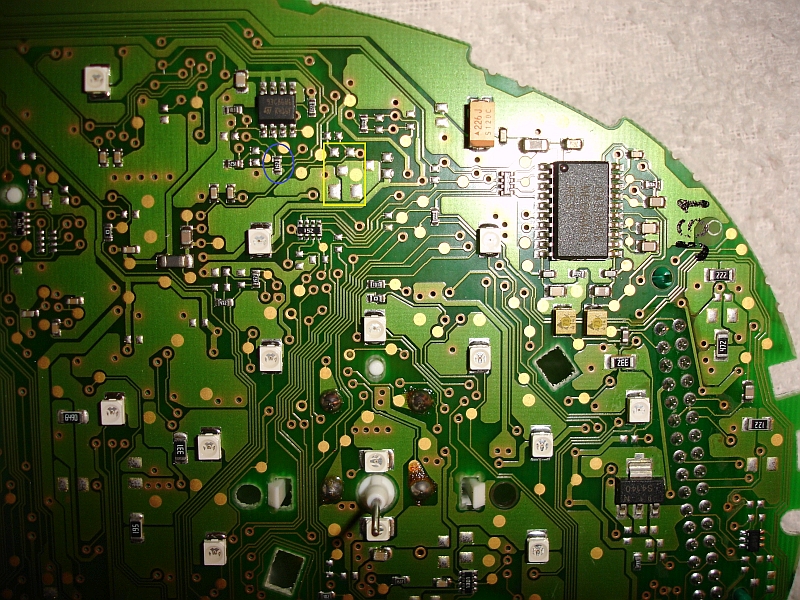

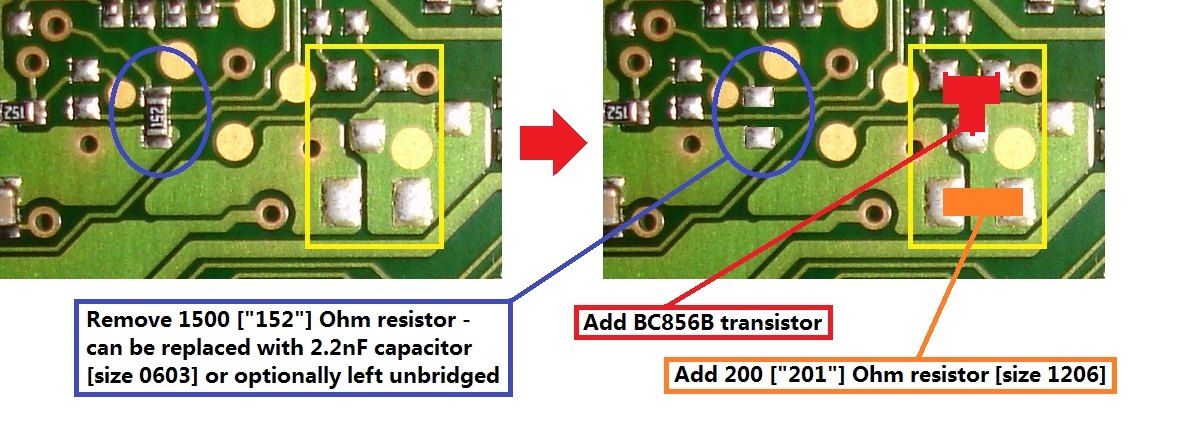

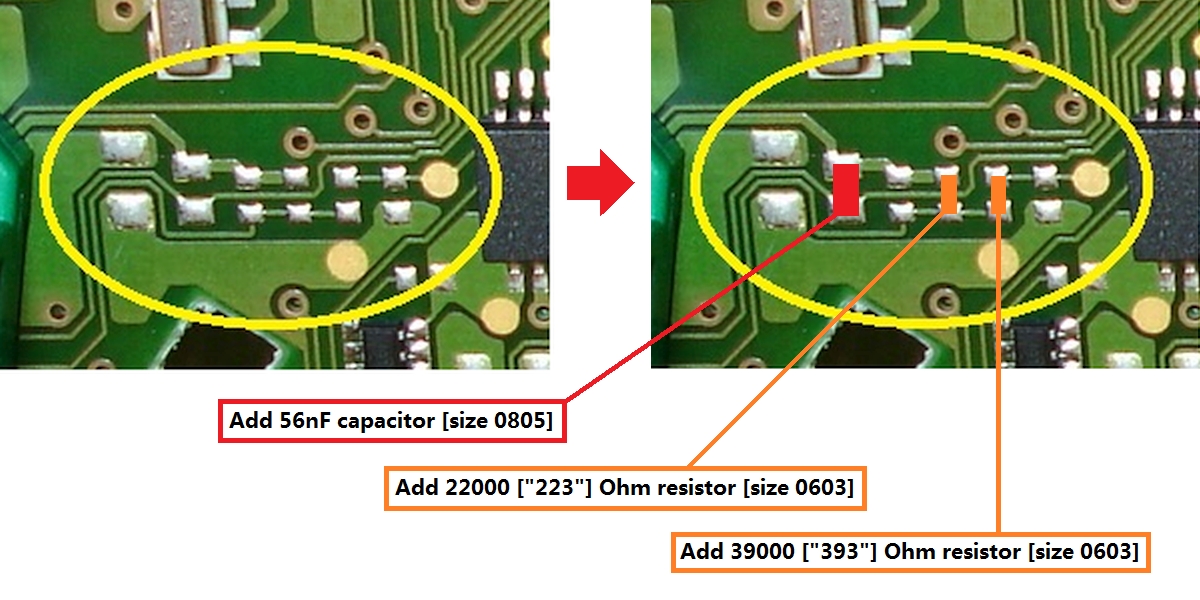

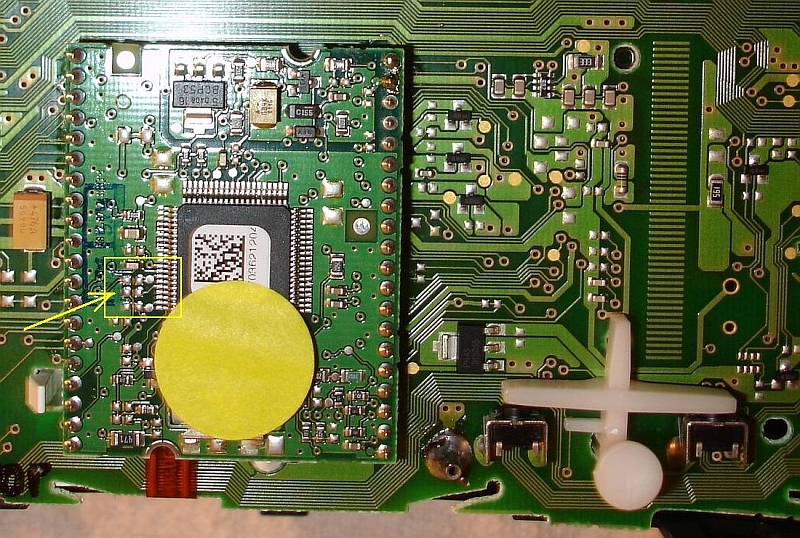

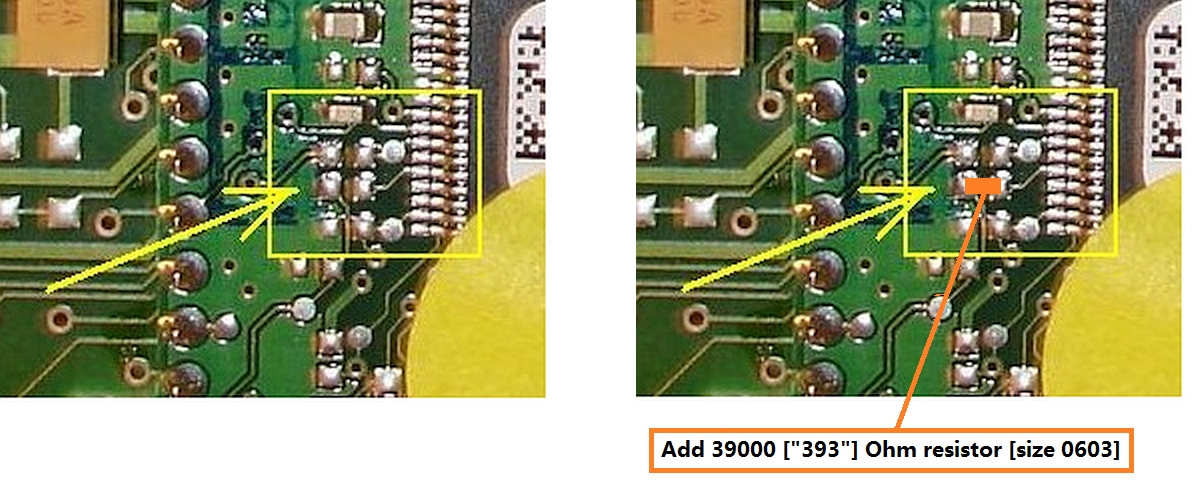

To install the components on the front side of the circuit board requires the needles, foils and the white plastic light duct to be removed. The components are also very very small, so some soldering skill is required.

When the radio clock is synchronised to the transmitter time, a small radio transmitter icon appears in the top left corner of the clock display.

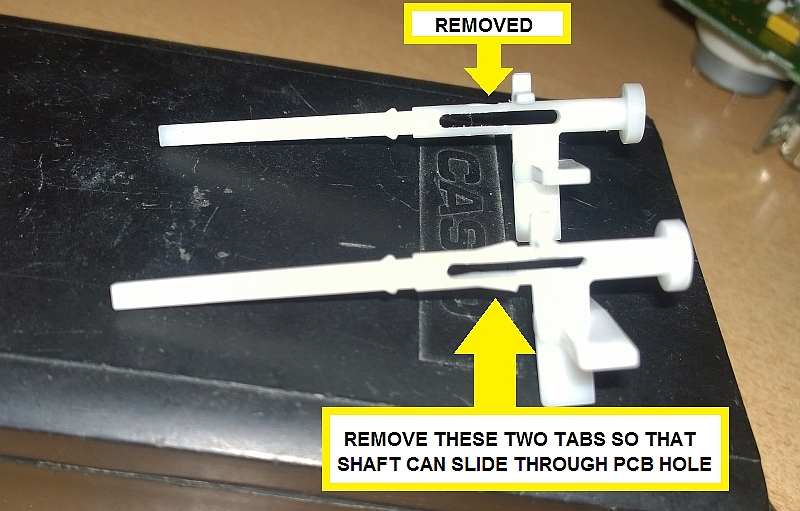

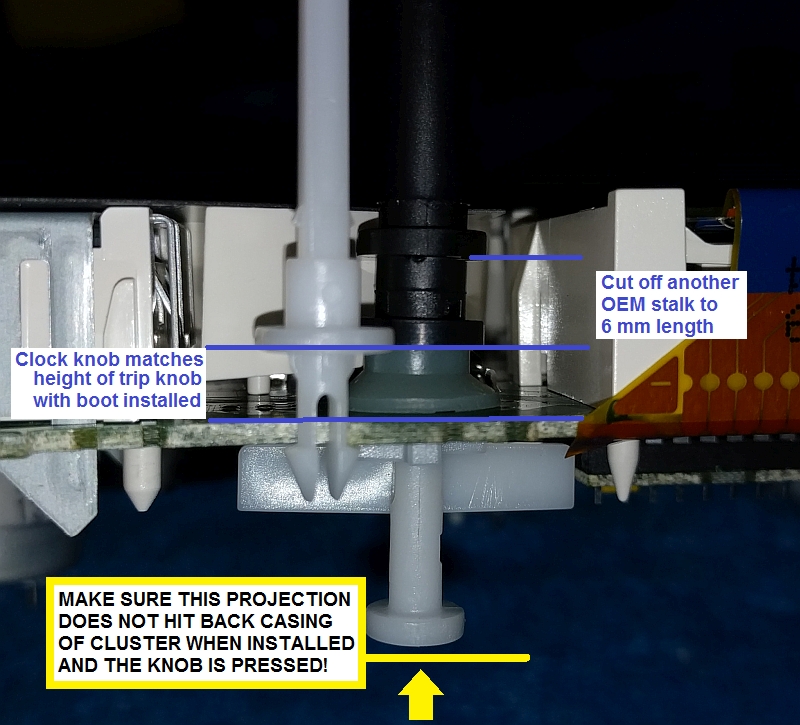

The clock button also has to be modified to enable it to be pressed in (similar to trip button). This is to allow you to switch the system on/off manually. This is a useful function if you park your car for extended periods (more than a week) to avoid battery drain. If you do not modify the clock button then you have to switch the function off via EEPROM. Parts to modify the clock button need to be obtained from another cluster!